THE ADVANTAGE OF BUILDING ON A SOLID FOUNDATION

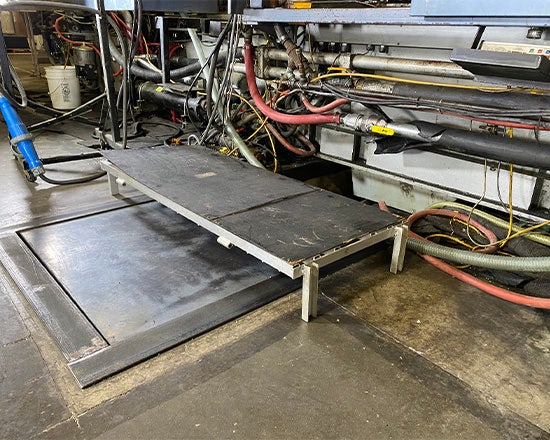

A US manufacturer of helicopters in Texas had a machining center with two challenges. Their first challenge was to raise their employees to the proper height for easier, safer access to machines when changing out parts necessary for manufacturing operations. The second challenge was regarding hoses, wires, and pipes. Not only did the pipes and hoses need protection, but more so, the employees needed protection from them. Hoses, wires, and pipes were in walkways and high traffic areas and created multiple trip hazards. Relocating or removing those hazards wasn’t an affordable option. They needed to be covered.

Traditional platforms posed several disadvantages. Those built on-site using lumber and plywood not only require extensive planning, labor and a higher purchase price, often times, sides are enclosed, eliminating the ability to route and cover their hoses, wires and pipes. Plus, plywood by nature is porous, absorbing oils and fluids that not only break down the plywood, but also become slick and hazardous. Yet another disadvantage, once a wood platform is assembled, there’s no going back to reconfigure without starting over.

Metal fabricated platforms were another option under consideration. These would allow for the passage of hoses, wires, and pipes, but like wood platforms, they require onsite fabrication, many hours of labor, downtime and triple the out-of-pocket costs. Assuming the metal isn’t welded together, it’s possible to disassemble and reassemble in a different configuration, but not without significant and costly rework, manpower and downtime.

In search of a viable, economical, and reconfigurable option, the manufacturer came across FOUNDATION modular work platforms. They reached out to Wearwell with questions and in hope of a recommendation. Based on the challenges, goals and objectives, FOUNDATION was found to be the platform system that would meet their demanding requirements. The manufacturer was beyond relieved to have one flexible solution for all their challenges.

GOOD ERGONOMICS PLUS ANTI-FATIGUE SUPPORT KEEP CREW MEMBERS PRODUCTIVE

The first FOUNDATION order was for four 8” tall kits with smooth tiles. The manufacturer was surprised by how quickly the installation went. They easily did it start to finish themselves. This proved to be a significant cost savings over what they had been considering – hiring a contractor to custom build a platform for them. They were also impressed by the lead time, receiving everything they needed within just 4 days.

The FOUNDATION platform system worked so well that the manufacturer asked for samples of the open and diamond-plate versions for other manufacturing areas. This resulted in an additional order for 6” tall Foundation Work Platform Kits with Diamond-Plate Traction Surface to be used at another challenging workstation.

Wearwell's proprietary no-slide anti-fatigue matting, was added on the work platform to boost anti-fatigue support for standing workers.

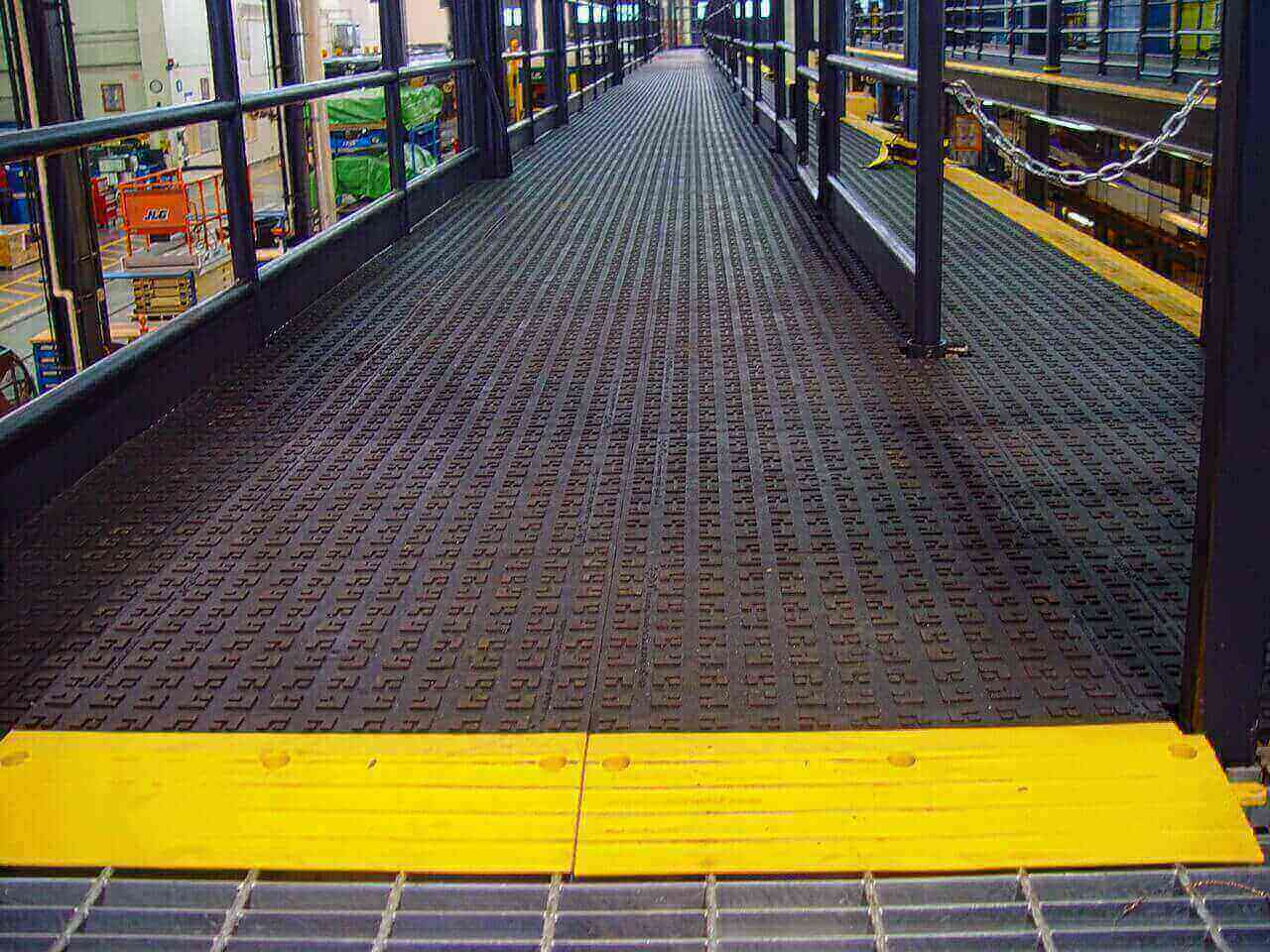

In yet another area, 12” tall kits with open tiles were installed to allow drainage, provide more elevation, and deliver greater traction and safety. In addition, the manufacturer can rest assured, knowing that with FOUNDATION'S 400 lb. load rating and chemical resistant tiles, their platforms will stand the test of time.

FLYING HIGH FROM THE FOUNDATION UP

This customer’s experience is a perfect example of how FOUNDATION’s versatility and ease of use reduces costs, downtime, labor and the hazards of slip, trip, and falls. All of this in addition to improving the health and safety of employees. The benefits appreciated by this one manufacturer:

- Easy planning and configuration for the workspace

- Choice of heights and surface patterns

- Quick and easy assembly on site, no contractors needed

- Short lead times

- Beginning to end cost savings

- Ability to protect hoses, wires, and pipes and protect workers from trip hazards

- Always ready for reconfiguration and customization with changing workspace requirements

Experience the #1 Brand in Ergonomic Flooring and Anti-fatigue Matting

Want to find out how Wearwell Ergonomic Flooring and Anti-fatigue Matting can help your company improve safety, health and productivity? You’ve got options!

Give us a call – Human sales and support agents are here to help you 800-264-3030

Request a catalog - Explore the widest range of industrial, commercial, retail anti-fatigue solutions all in one place

Calculate your ROI - Find the true return on your ergonomic, anti-fatigue flooring investment for your company