A ZIG ZAG LINE TO A SAFER SOLUTION

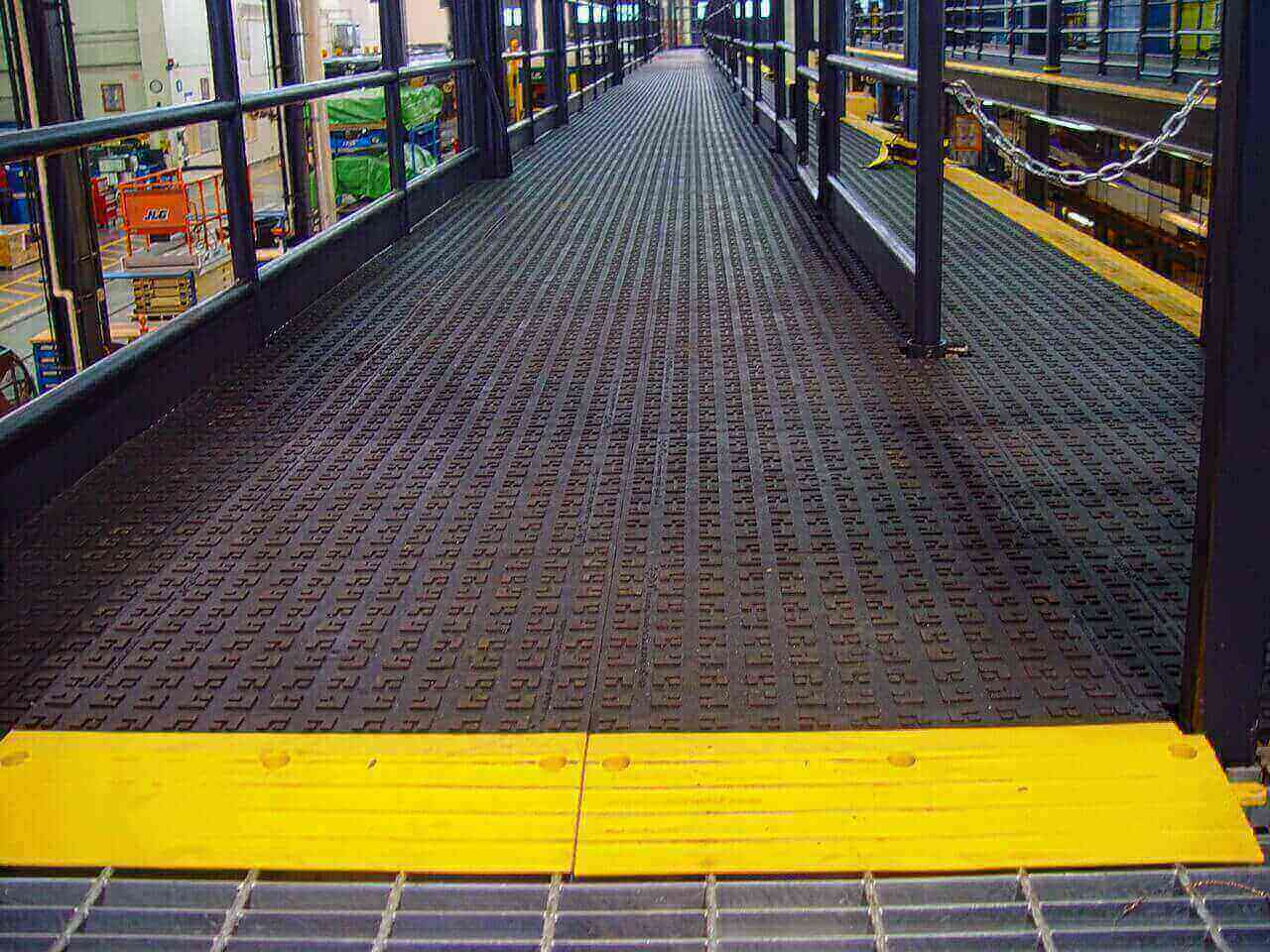

A Japanese auto manufacturer in Indiana, known for their prestigious vehicles and a long-standing Wearwell customer, had been using gray Diamond-Plate anti-fatigue mats (no. 415) on their main assembly line. They were experiencing issues, though not with the product or performance. In fact, they continue to purchase the product for other areas to this day. The customer realized that the assembly line had a unique set of challenges.

The manufacturing line was an unusual, zig-zag shape. To provide ergonomic relief to their employees, the facility has for a long time used multiple mats turned different directions to fit the space. The customer discovered that the situation introduced trip hazards as employees transitioned from one mat onto another. Small carts were also used which inevitably ripped and curled the matting edges. The customer attempted to solve these problems by taping the edges of the mats to the floor.

STUCK WITH STICKERS AND TAPE

Another complaint was the routine repair and replacement of floor stickers, paint, and tape used to mark hazardous areas. Wearwell introduced the customer to ErgoDeck Diamond-Plate (no. 590) and demonstrated the advantages of this highly customizable ergonomic flooring system. The customer enthusiastically chose black tiles for their main assembly line and charcoal tiles to indicate changes of direction.

As a durable replacement for expensive yellow tape, yellow ErgoDeck Smooth 3” strips were used to define the two areas.

COLOR CODING FOR WORKSPACE DIFFERENTIATION - A COMMON SENSE SAFETY IMPROVEMENT

The next area that needed address was where machinery was used that created RFI (Radio Frequency Interference). It was crucial that employees with pacemakers and insulin pumps were warned of the hazard to their health.

Historically, this kind of risk was indicated with yellow tape and spray paint. Now, in a cost and maintenance saving improvement, the product of choice was ErgoDeck 590 modular ergonomic tiles in safety yellow.

ErgoDeck eliminated the maintenance of paint and tape and added long term durability to the safety solution plus, ErgoDeck's strength provided the necessary support for the machine.

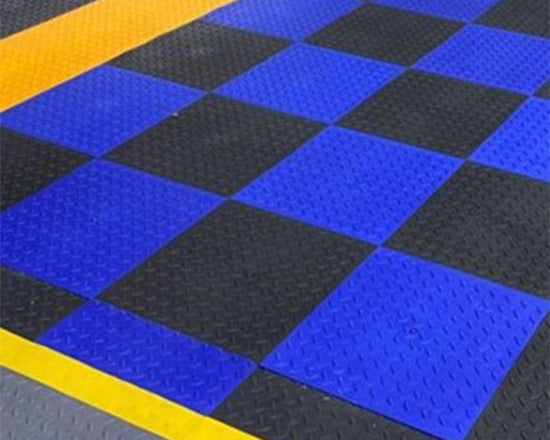

The final challenge was a big one - two hazards in one area. The customer had been using orange markings for overhead dangers where employees worked under suspended vehicles. Blue markings called attention to moving equipment such as the hydraulic-assisted arms that install glass, tires, doors, and seats.

(The proprietary nature of the machinery in this area prohibited photography)

Blue markings called attention to moving equipment such as the hydraulic-assisted arms that install glass, tires, doors, and seats. A combination of ErgoDeck colors can proved to be the ideal solution.

ErgoDeck 590 orange was installed to call out overhead caution and a checkerboard pattern of ErgoDeck 590 black and blue to indicate moving equipment.

In addition, orange ErgoDeck Illuminate (a light system) was installed in 400’ long pits where under body work was performed. This provided the upward light necessary for clear visibility and quality assurance.

For production time phase indicators, ErgoDeck yellow 3” strips were installed along the full assembly line for optimal manufacturing efficiency.

SAFETY IMPROVEMENTS POWER RESULTS ON ALL CYLINDERS

ErgoDeck colored modular tiles saved on the costly replacement of floor tapes and stickers, but the cost savings related to painted floors were tens of thousands!

The hard costs of industrial floor paint averages $140 a gallon and it’s roughly the same for sealants. One gallon covers approximately 300 square feet if applied conservatively.

Paint requires an extensive amount of labor- not just applying the paint, but preparation, too. Floor preparation involves patching any holes or cracks and chemical etching to ensure paint adhesion. If any old paint is present, the concrete has to be treated with a solution to dissolve the paint and a grinder for complete removal. It then has to be thoroughly cleaned. Of course, the area is off limits during all of that time.

Once applied, floor paint requires 48 - 72 hours to cure and the same is true for a sealant. Even for small areas the preparation, painting and sealing can take up to 9 days. That’s 72 hours of lost production for a single shift. With on-going maintenance and repair, the labor, lost productivity, and costs never end.

Then there’s the savings of trip hazards. By replacing multiple mats with one continuous surface, the company mitigated the risks of trips and falls. With an average workers’ comp claim of $41,353, that was definitely a worthwhile investment!

The final ErgoDeck installation exceeded the customer’s expectations for its aesthetics, functionality, versatility, and value! Their $500K investment in ErgoDeck more than paid for itself in under a year. Those savings don’t include all the health and ergonomic benefits that their previous floors was missing. All in, the company’s cost savings exceeded $2M in just the first year!

Better still, the facility looks amazing! The professional appearance is a positive reflection of the company and their dedication to employee health. Needless to say, this Wearwell customer is now proud to show off their facility on public tours and to potential customers!

Experience the #1 Brand in Ergonomic Flooring and Anti-fatigue Matting

Want to find out how Wearwell Ergonomic Flooring and Anti-fatigue Matting can help your company improve safety, health and productivity? You’ve got options!

Give us a call – Human sales and support agents are here to help you 800-264-3030

Request a catalog - Explore the widest range of industrial, commercial, retail anti-fatigue solutions all in one place

Calculate your ROI - Find the true return on your ergonomic, anti-fatigue flooring investment for your company

Learn more about ErgoDeck- Find more information about ErgoDeck to better suit your needs