Slips and falls – something you don’t think about, but looking back you should have known it would happen.

Life gets hectic at work with time management challenges and deadlines. It’s easy to lose focus. When workers get into a groove at work, autopilot takes over. Being mindful of the work environment can prevent costly slips and trips from happening. After all, one misstep can create lifelong pain, and most of the time it could have been prevented!

Major Causes of Slips and Falls at Work:

Surface Height Differences

Surface Height Differences

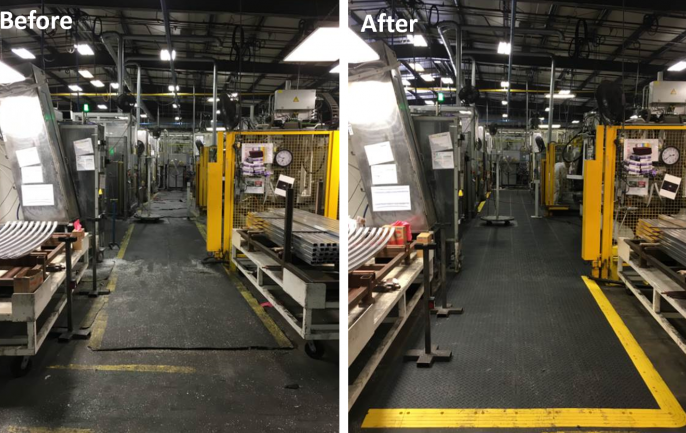

Consider the smoothness of the floor surface, over time, small protrusions, worn uneven mats, and planal shifts between in the surface occur and are often ignored. Rather than fixing the problem, human instinct usually chooses to work around it.

While workers focus on their work, part of their brain is now subconsciously moving them around the hazard. This means workers cannot focus 100% of their attention on the job at hand, and it means you are essentially making a bet that their subconscious will avoid a hazard at a statistical rate of 100%, day after day. Whether that’s 10/10 times per day, or walking over an uneven surface 1000 times a day. The odds of something happening just one time will have you looking back and kicking yourself for not fixing the hazard in the first place.

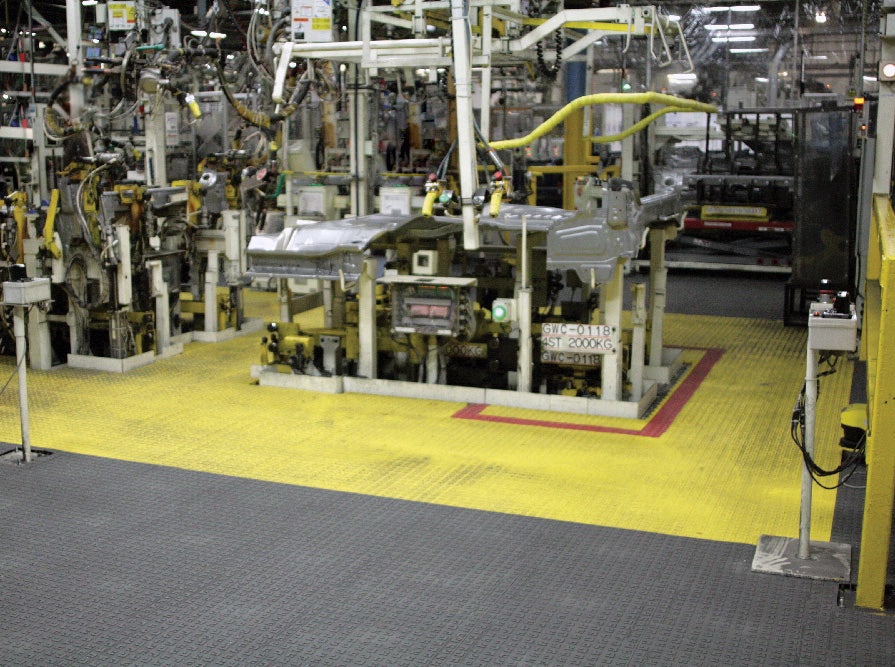

One recommendation is to elevate the users above the hazard with ergonomic or slip resistant flooring like ErgoDeck. These types of ergonomic flooring can cover up damaged concrete, elevate users above small protrusions, and can even be used on a sloped floor without causing a hazard.

Surface Exposure to Wet and Oily Environments

Surface Exposure to Wet and Oily Environments

Many people work in environments that are wet, oily, slippery, and overall difficult to stand on. Slippery floors are a major cause of injury, and many injuries come from simple near-fall reactions (where someone catches themselves but is injured due to the reactionary movement.) Slippery areas MUST be addressed with a proper traction solution. There are several wet area or dry area ergonomic mats and safety floors that provide traction, allowing users to safely walk across the plant and work more efficiently in these environments.

Miscellaneous Flooring Hazards

Miscellaneous Flooring Hazards

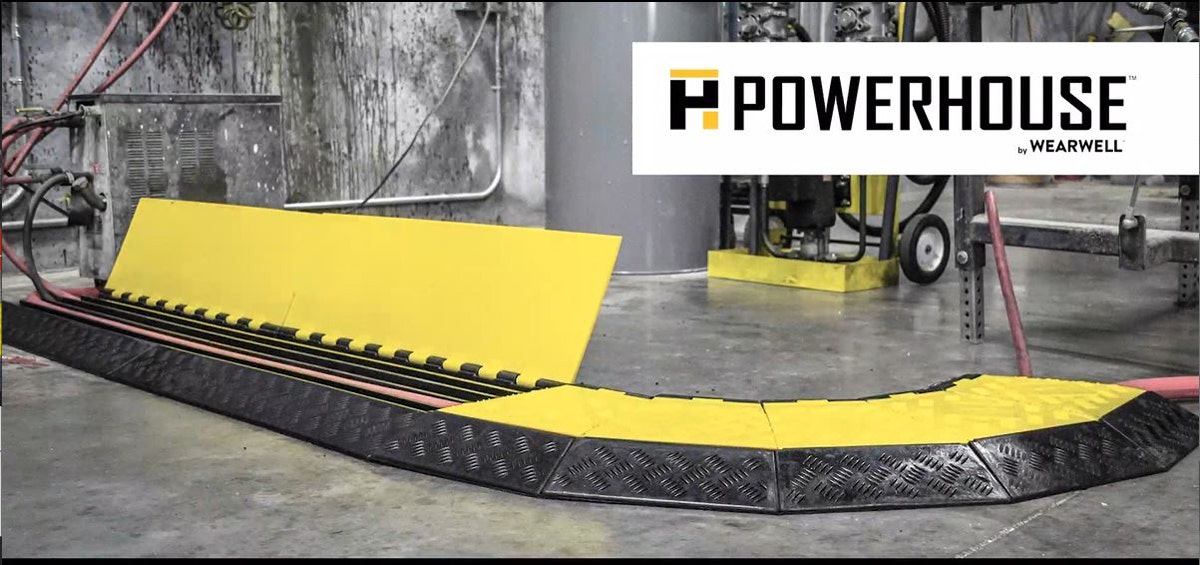

Stray cords, cables, air hoses, and other miscellaneous items used in the workspace should always be taken into consideration as a slip/trip hazard. Ask employees and be on the lookout to see if workers are stepping over or on any stray cords during the course of their shift.

One way to approach this is to have cable lines come down from the ceiling. When this is not feasible and lines must run across the floor, cable protection is the best way to protect personnel from dangerous slips and falls.

Prevent and Prepare:

To be prepared for the worst- we need to think ahead. What are some ways to prevent slips and falls?

Visibility

Visibility

Use bright colors to alert workers of floor height differences, steps, and to outline workstations. Tapes can be used, but they don’t last in the long-term and require ongoing maintenance. High visibility ergonomic flooring can be used to help workers avoid hazards.

Be sure that any change in floor plan has a high visibility outline. This can mean a yellow safety border on a workstation mat, or a yellow safety ramp to allow for a smooth transition between concrete and an ergonomic floor.

Traction

Traction

Utilize mats and floor solutions that help keep your feet on the ground. Whether it be a dusty dry area, oily conditions, or a predominantly water-based environment, there are flooring and matting options specifically engineered for each of these areas. If not required already, encourage workers to wear sturdy shoes that keep good traction and support.

Organize Floor Hazards

Organize Floor Hazards

An organized and maintained work environment is key. Keep cords out of the way with cable protection and find flooring that fits your conditions to prevent injuries. Whether you are in the general manufacturing, food service, laboratory, or fulfillment industry, there are a variety of options that will reduce slips and falls in your workplace while optimizing efficiency and maintaining workflow.

Should Have, Would Have, Could Have

Looking ahead and preparing your work environment for the “should have knowns” will prevent injuries while increasing certain efficiencies and time management. Don’t wait until the injury happens. Look ahead at what areas in your work environment might be a hazard, and consult with a professional if you aren’t 100% sure.

Prevention helps everyone in the company. Both managers and workers will have one less thing to worry about. Continual maintenance of the work environment is the best way to boost employee safety, morale, and show workers that the company is committed to their overall wellbeing. Odds are that investing in solutions that reduce workplace injuries will be worth your while!

Regardless of your industry or work environment, Wearwell has a solution for you. Contact us or call 888-413-7317 to find out what ergnomic flooring or matting is right for you.