The Importance of Adopting Lean

|

|

What happens when an unanticipated increase in demand leaves your manufacturing work cells in complete disarray? This is when you see production bins piling up, product defects, a growing backlog, and worst of all, injured Industrial Athletes. If you’ve encountered this situation, then you need to invest the time in adopting lean manufacturing work cells. |

What is a Lean Work Cell? |

|

|

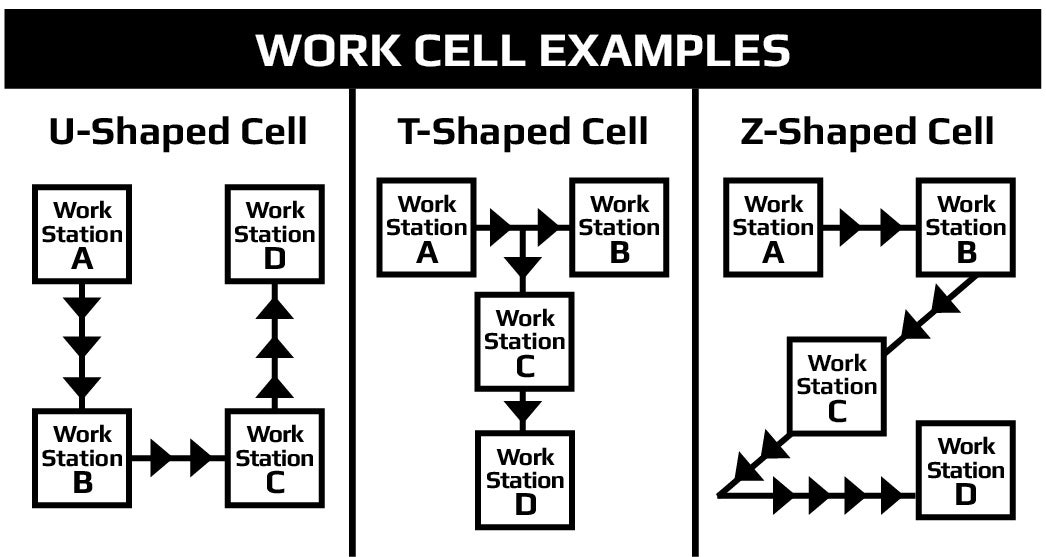

A lean work cell is comprised of multiple smaller workstations. These workstations are near one another to ensure a seamless flow of work from one operation to the next. Work cells should be segregated by homogeneous work operations. An example would include an entire work cell for assembling subcomponents where each workstation within the cell represents a different portion of the assembly process. |

Work Cell Designs |

|

There are several lean work cell designs. T-shaped cell designs are ideal when multiple raw materials are required, or different product types are being manufactured simultaneously. U-shaped cell designs allow Industrial Athletes to access individual workstations while ensuring work easily moves between those workstations. S-shaped and Z-shaped cell designs are ideal for setting up workstations in and around obstructions like pillars, posts, and large stationary equipment. All of these designs adopt simple lean principles. First, there must be clearly defined entry and exit points to and from the work cell for work-in-process parts. Second, distances between workstations within the work cell must be optimized so transit times are minimized. Third, the work cell must be spacious and free of obstructions, while allowing for easy access to equipment and tools.

|

|

Relying Upon your Industrial Athletes |

|

Your Industrial Athletes should be active participants in redesigning lean work cells. They should be seen as vital contributors. They have invaluable insight into what causes work stoppages, bottlenecks, and injuries. Having them work with you when redesigning your work cells guarantees everyone takes ownership and adopts the process. So, what steps should you take to design lean work cells? |

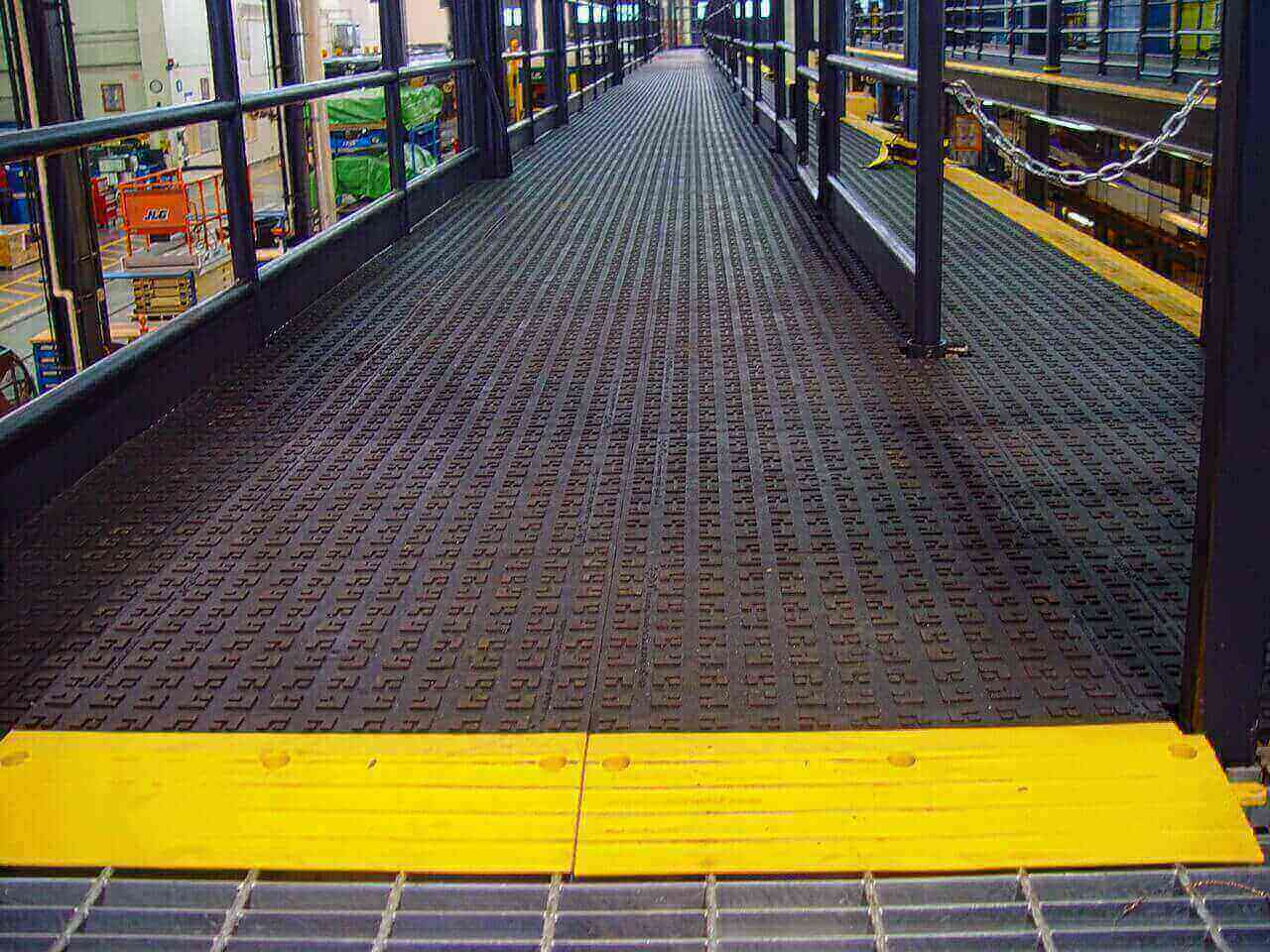

1. Disassemble Existing Stationary Work PlatformsStationary work platforms are cumbersome, extremely heavy, difficult to work around, and time-consuming to assemble and disassemble. Your Industrial Athletes have probably learned to deal with these obstructions, but now is the time to do away with them once and for all. Ergonomic work platforms such as Wearwell’s FOUNDATION are ideal solutions because they were designed with lean concepts in mind. These platforms are sturdy, lightweight aluminum platforms that are easy to assemble and disassemble. Most importantly, they’re much less expensive when compared to those archaic work platforms of the past. FOUNDATION easily allows you to adjust to an expanding shop floor. These platforms are designed to grow as you grow, allowing you to increase your production space with minimal downtime. Most importantly, they’ll raise your Industrial Athletes to the correct height while protecting them from everyday obstructions. 2. Remove All Standard Rubber Tile FlooringStandard rubber tile flooring puts your Industrial Athletes at constant risk. The gaps between these flooring solutions invariably lead to trips and falls. Increased traffic only increases these gaps. You’ll need to replace these old rubber flooring tiles with a modular anti-fatigue matting solution like 24/Seven® LockSafe®. Your employees must be able to easily access different workstations within your newly designed work cell. 24/Seven® LockSafe® is an ergonomic flooring solution that uses a patented “Positive Interlock System” holds tiles secure but can be “unzipped” for reconfiguration. Most other solutions have passive connections that rarely, if ever, stay together. In the end, your Industrial Athletes will be able to walk on a seamless ergonomic matting solution with excellent crush resistance and superior comfort. 3. Incorporate Illuminated and Color-Coded Anti-Fatigue MattingAfter removing the standard rubber tiles, it’s time to identify dimly lit areas within the work cell by adopting cost-effective solutions like ErgoDeck® Illuminate tiles. These tiles have separate channels that can accommodate up to five different colors of LED lighting, allowing you to light up a given area from the floor up. The practice of identifying workstations, material storage locations, and high-risk safety areas with expensive industrial paint must become a thing of the past. Wearwell’s complete line of ergonomic color-coded flooring tiles will not only save on the upfront cost of floor paint, but the endless wear-repair cycle that paint is notorious for. Both solutions allow you to integrate all your color-coded safety protocols into one cohesive flooring system. Industrial Athletes will easily be able to identify different production areas while being more aware of everyday hazards. 4. Define Workflow and Choose Work Cell DesignUnderstanding how work moves from one workstation to another is critical in work cell design. You’ll need to discuss how work should flow with your Industrial Athletes. You may need to reposition existing equipment or adjust the distance between workstations. Mapping out how work moves between workstations within the work cell with a diagram will go a long way in simplifying which cell design you choose. 5. Protect Cables, Wires, and Heavy-Duty HosesCables, wires, and heavy-duty hoses should always be placed away from high traffic areas and if possible, the placement in the interior of work cells should be avoided. If individual workstations have stationary equipment, then the cables should be routed underneath or on the outside of the work cell. Regardless of whether your cables are exposed or not, you should protect them with cable protectors or elevate your Industrial Athletes above them with the use of platforms like FOUNDATION. By implementing one of these measures, you’ll protect both your hoses from damage and your team from trips and falls. 6. Adopting 5S (Sort, Set, Shine, Standardize, Sustain)The next step is to make sure that there is ample space for Industrial Athletes to handle incoming and outgoing bins of semi-finished products. They will also need to clean up the cumbersome work cell once and for all. How is this done? Well, the solution lies in adopting 5S.

Adopting lean manufacturing is a never-ending process. After you’ve redesigned your lean work cell, you should periodically assess how it’s performing, relying upon the insight of your Industrial Athletes. A safe, efficient operation is a successful one! |

|

Still have questions? Reach out to us to let us know how we can help. |

| Contact Wearwell |

The Importance of Adopting Lean Manufacturing Work Cells

February 14, 2022 | View: 3569 | Categories: Ergonomic Flooring, Work Platforms, Floor Mat Basics | Tags: ErgoDeck, 24/Seven LockSafe, Ergonomics, Foundation Work Platforms | By: Abram Buck