A Welder’s Struggle Is Real

Anyone that knows a Welder, or is a Welder themselves, can appreciate the rigors of the job. Day in and day out, Welders are expected to work hard in a demanding environment while working on hard, unforgiving concrete. Sadly, too often these dedicated workers, come to accept that the resulting aches and pains are just part of the job. It shouldn’t be and doesn’t have to be.

Health and Well-being

Health and Well-being

There’s science behind the aches and pains of a Welder. Standing in one place on hard surfaces creates a static position that doesn’t engage the muscle movement necessary for circulation, causing swelling in the lower extremities. The inherent hardness of concrete doesn’t absorb impact. Concrete reflects it. The human body feels the damaging effect on the lower back, legs, feet, and joints. Overtime, any number of these can evolve into debilitating MSD’s.

Productivity and Performance

When workers suffer, businesses suffer. The health of Welders (and any standing worker) has a direct effect on their productivity and performance. Quality welds and fabrication take an enormous degree of precision and focus. Even the best Welders find it hard to ignore the painful effects of standing on concrete. The farther they are into their shift, the greater the distraction of fatigue and pain and thus, the likelihood of less than quality work.

Morale and Retention

Like so many skilled trades, Welders are in high demand and short supply. Businesses can’t afford to lose these workers if it can be avoided. It can. Investing in anti-fatigue matting demonstrates that their employer cares about their health and well-being. Gallup research has consistently shown that companies that show their commitment to employees, by providing them with the tools they need, improves employees’ morale and dedication.

Anti-fatigue Mats for Welding Do Exist

Anti-fatigue Mats for Welding Do Exist

Not all anti-fatigue mats can hold up to the high demands of welding conditions. Most employers know this firsthand and resist the use of mats altogether. Mats may all look the same, but they don’t all perform the same.

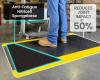

Wearwell’s WeldSafe welding mats have a unique SBR rubber surface with a melting point of over 500⁰ Fahrenheit. The fatigue-fighting support comes from the proprietary Nitricell sponge base. It absorbs repeated compression and bounces back better than any PVC sponge alternative.

Wearwell offers welding mats in 2 surfaces - lightly textured and diamond-plate, both versions are proudly made here in the USA. Accept no substitutes in your welding operations! Adding floor mats to the work environment is one of the easiest, most cost effective improvements a company can make.

Learn more about WeldSafe from Wearwell.