Challenges Come With the Territory

Manufacturing and processing facilities may produce different products, but they all share the same safety challenges. The most obvious prevention is PPE (Personal Protection Equipment). PPE such as hearing protection, safety glasses, protective gloves, high visibility clothing, and others are mandated based on the unique risk factors of each job.

However, the one risk factor that is common across ALL employees in all jobs is the facility floor. It’s the one element that affects the health and safety of every employee day in and day out.

Across all industries - manufacturing, food processing, distribution, and many others- employees suffer the effects of standing on hard, unforgiving concrete floors. The human body feels the damaging effects on the spine, legs, feet, and joints. Overtime, any number of these can evolve into debilitating MSD’s.

Ergonomic flooring and anti-fatigue matting is the most overlooked and underestimated health and safety solution. Although anti-fatigue matting and flooring isn’t mandated by OSHA like PPE, it doesn’t make the need for a solution any less critical.

As the awareness of MSDs has grown, more and more businesses are instituting anti-fatigue flooring programs for their workplace, particularly in larger, more complex areas.

The most common type of ergonomic flooring is a modular system made up of 3’ x 3’ rubber tiles. These systems may look similar, but they have very distinct differences in their ability to stay connected.

For Modular Rubber Mats, There Are 2 Types of Interlocking Systems:

One type, and the most common system, has PASSIVE connections.

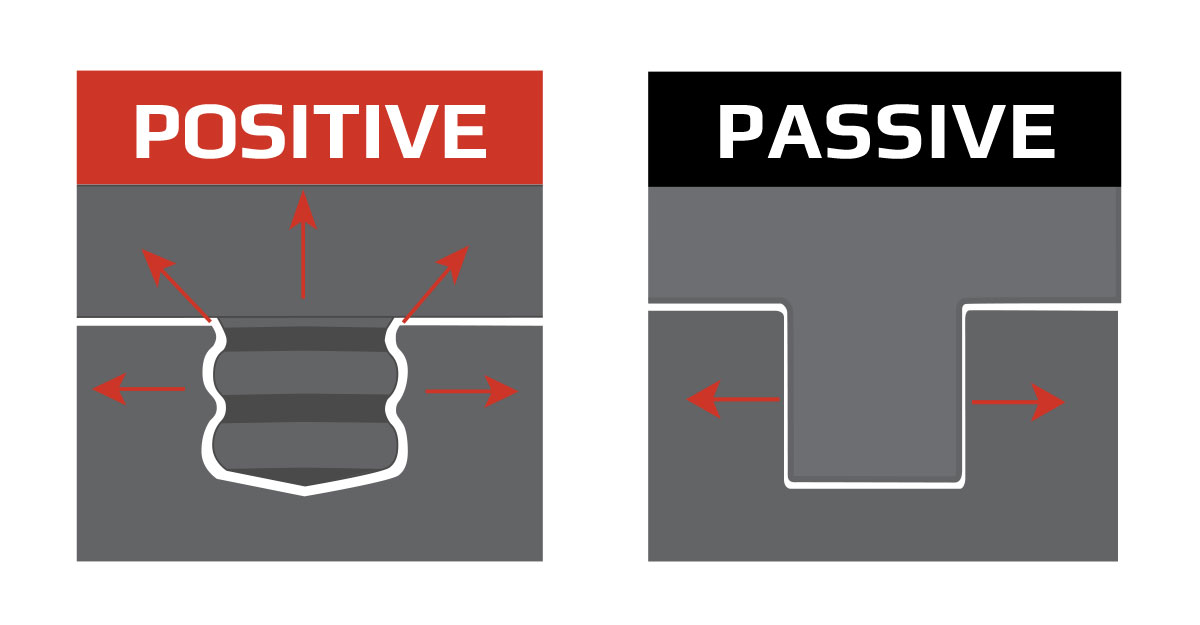

Passive connection systems simply “lay in”. The male and female connectors “nest” together, relying on the weight of the mat to hold the connection. This type of interlocking system looks nice upon initial installation. However, it doesn’t hold together well in-use. These interlocks rely on the weight of the mat itself, making the connection susceptible to any upward movement. These types of modular tiles can easily separate with any misstep as workers walk in and out of the workspace.

Users of these types of mats find themselves reconnecting the tiles all the time, or they attempt more permanent fixes. The most common methods used are zip-ties, glue, and tape. Depending on the method used, these so-called fixes are unsightly, introduce additional trip hazards or the tiles are so permanently connected, that they can never be reconfigured (which is the primary benefit of a modular system in the first place). If this sounds familiar then you can understand the endless frustration.

Above is an example of modular rubber mats with failed, passive connections.

The second type of modular system features POSITIVE connections. Designed and patented by Wearwell, 24/Seven LockSafe is the only modular tile with a positive interlocking system. Both male and female connectors feature corresponding ridges that lock together, providing a strong connection in in every direction. In fact, assembled sections can be rolled up for maintenance and rolled back out without the time and hassle of reassembly. If or when the area needs to be replaced or reconfigured, the individual tiles can easily be “un-zipped” apart.

The difference between the passive and the positive connection system of 24/Seven LockSafe is clearly demonstrated in this video.

Above is an example of 24/SEVEN LockSafe with positive connections. (Solid version shown. Tiles also available for drainage, ESD and Food Processing)

The Conclusion

Change is good! Passive connection systems have been around for decades. And for decades users have come to expect, and live, with the failures. But the frustrated, don’t have to be frustrated anymore! With 24/Seven LockSafe, lost time, high costs and endless annoyance is a thing of the past!