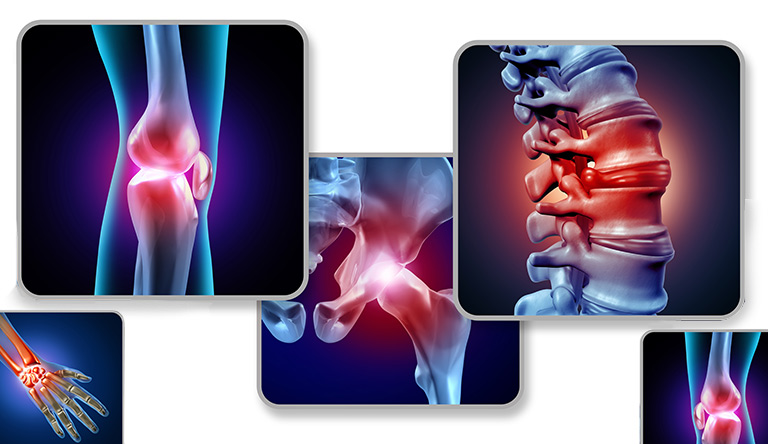

Musculoskeletal Disorders (MSDs) are excruciatingly painful and often debilitating for those affected. They are the leading cause of workplace absenteeism, lost productivity, and increased medical, disability, and workers' compensation costs making them extremely expensive for employers.

MSDs are injuries or disorders that affect the muscles, tendons, nerves, cartilage, joints, and spine that develop gradually over time due to overuse and make everyday tasks challenging. For example, walking, bending down to tie your shoes, standing, using a keyboard, holding a pen, or lifting a light object can feel next to impossible for those with MSDs.

The costs of Musculoskeletal Disorders for employers are staggering. According to the Bureau of Labor, MSDs are the highest workplace injury and responsible for almost 30% of all workers compensation costs, with a direct cost of almost $15,000 per employee.

There is a general lack of understanding or empathy for people with musculoskeletal disorders. As a result, others may think of them poorly when the reality is that they are suffering from diagnosable conditions. Because of this poor public perception, people with MSDs often report feeling isolated, which can harm their professional, social, and mental well-being.

The Causes of Musculoskeletal Disorders

According to the National Institute for Occupational Safety and Health (NIOSH), there is a direct correlation between working conditions and Musculoskeletal Disorders.

Almost all industries are prone to the condition - manufacturing, distribution, and food processing, to name just a few. This is due to the physically demanding nature of their work, which includes heavy lifting, over-reaching, awkward positions and working on hard surfaces.

Muscles: Muscles produce by-products like lactic acid, which gets removed by the body. However, muscles used for extended periods do not have enough time to remove the by-products, which irritates the muscle and causes pain.

Tendons: Some tendons, like those in your hands and wrists, are lubricated by your body so they can slide back and forth freely. However, repetitive movements can cause the lubrication system to malfunction resulting in excess friction that can cause swelling and inflammation. Other tendons, like in the shoulders, can tear when tensed repeatedly or from friction with the surrounding area caused by swelling.

Nerves: Muscles, tendons, and ligaments surround nerves. Awkward and repetitive movements can cause swelling in the surrounding tissue, which squeezes or compresses the nerves causing muscle weakness, pain, and numbness.

Common Types of Musculoskeletal Disorders in the Industrial Market

Back pain: According to the CDC, chronic back pain is one of the top ten reasons people go to the doctor in the United States. Of workers affected, fabricators, operators, and laborers make up the majority, likely due to long periods of standing, carrying heavy loads and poor posture.

Back pain: According to the CDC, chronic back pain is one of the top ten reasons people go to the doctor in the United States. Of workers affected, fabricators, operators, and laborers make up the majority, likely due to long periods of standing, carrying heavy loads and poor posture.

Arthritis: There is a common misconception that arthritis only affects the elderly. However, according to the CDC, over two-thirds of people with arthritis in the United States are under 65. Arthritis is a catch-all term for over 100 diseases and conditions affecting joints and the surrounding tissue. Arthritis is the most common form of disability in the United States, affecting over 46 million Americans.

Rotator Cuff and Tendonitis: Also known as Rotator Cuff Tendonitis this is an inflammation of the shoulder joint and often causes by the strain of repetitive over reaching and over-head work. Overtime this can cause severe injuries leading to physical therapy and in the worst case, invasive surgery.

Preventing Musculoskeletal Disorders

If you are serious about reducing MSDs in your organization, the following tips are a great place to start.

Mechanical Means: Introducing new tools or equipment can reduce or eliminate the physical strain on the human body. For example, using forklifts, carts, or conveyor belts to transport heavy materials instead of making employees manually lift them can be a big step towards eliminating potential injuries.

Preventative care: Identifying and treating employee aches and pains before they become more severe is crucial to prevention. In addition, stretching programs can prevent injuries, and pre-hire and periodic physical assessments can identify risk factors allowing management to make more educated staffing and placement choices.

New policies: Whenever possible, eliminate physical stress on employees. However, that isn't always an option, so introducing new company policies to reduce physical demands to as low as possible is the next best thing. For example, limiting shift duration and creating mandatory breaks can go a long way toward reducing MSDs. Also, instead of having one employee working on a physically demanding task their entire shift, rotate employees to lessen the stress and spread it out evenly.

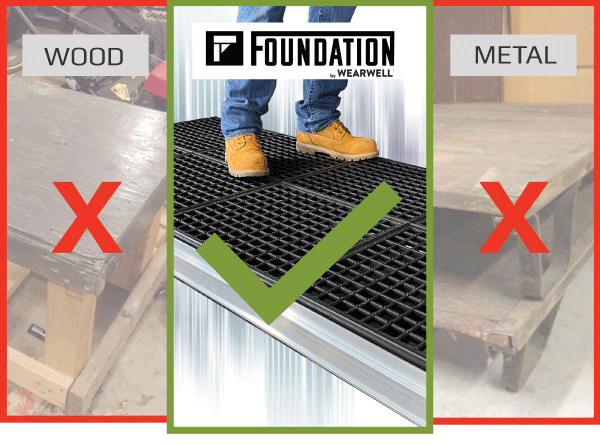

Work platforms: Many work areas and machines have no elevation or a single height platform for an average height person, but they do not accommodate to employees of different heights. Unfortunately, work platforms with the one-size-fits-all approach forces many workers to perform their jobs in awkward, uncomfortable, and potentially dangerous positions.

Work platforms: Many work areas and machines have no elevation or a single height platform for an average height person, but they do not accommodate to employees of different heights. Unfortunately, work platforms with the one-size-fits-all approach forces many workers to perform their jobs in awkward, uncomfortable, and potentially dangerous positions.

One solution is to replace everything with elevated surfaces. Often these are fabricated using steel or wood. The cost of materials, labor and downtime are significant and unrealistic for many organizations. Instead, a simpler, more affordable, and every bit as effective solution is introducing modular work platforms. These platforms bring workers into a more comfortable position and allow for easy replacement, adjustment, and reconfiguration. These elevated heights don’t just provide an optimum height for any employee; they provide a variety of surfaces from smooth to high traction. Additionally, employers can provide sure footing with diamond-plate or drainage work platforms.

Ergonomic matting: Many employees work for hours on hard concrete surfaces that have a negative effect on employees’ bone, joint, and muscle health. High quality anti-fatigue matting will reduce the impact on joints by 35% and minimize sciatica, shin splints, varicose veins, Plantar Fasciitis, and other Musculoskeletal Disorders. In addition, employees who are comfortable and not thinking about their aches and pains are more productive and have higher performance. Wearwell manufactures anti-fatigue matting, such as diamond-plate, that is available in standard sizes, custom lengths, widths, shapes and configurations. For ultimate on-site configuration, ergonomic flooring tiles offer ultimate modularity without comprising comfort.

Wearwell Will Help You Reduce Musculoskeletal Disorders

Organizations that want to protect their employees and their organization from Musculoskeletal Disorders must approach the subject proactively. Wearwell and our industry-leading anti-fatigue matting, ergonomic flooring and modular platforms can improve the health and safety of your team.

Let our nationwide experts assist you in choosing the best solution for your needs. Find your local expert or schedule a free on-site assessment.