Green Initiative

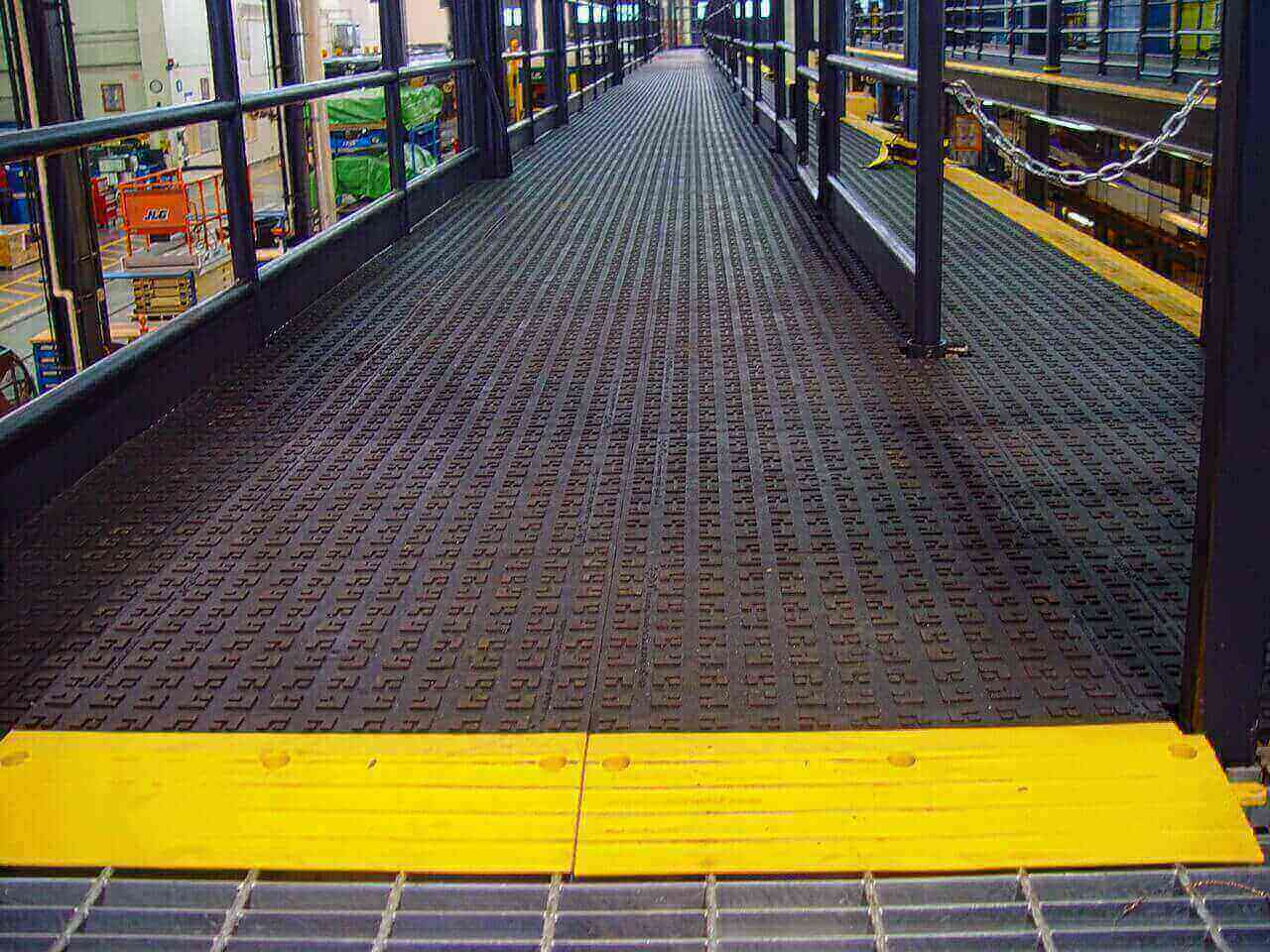

The very first products we manufactured in 1950 were produced from recycled automobile tires. Though production technology has changed since then, we still champion the use of recycled materials and overall energy conservation.

Today, we continue our environmentally friendly legacy at our Corporate Headquarters and manufacturing facility.

View Wearwell's Green Initiative Brochure

We’ve implemented state-of-the-art energy conversation technology and programs.

- TVA Green Power Switch Partnership Program. We buy over 5% of our electricity from renewable sources such as the sun, wind and methane gas produced by landfills and waste treatment facilities to reduce our carbon footprint.

- Sixteen (16) of Wearwell's 90 products utilize between 50 and 100% recycled materials. Another thirteen (13) contain between 33 and 50% recycled materials. We continue to investigate alternative compounds for all products when feasible.

- "Quick Start Monitoring" system by EST. We fully review all electrical anomalies, water flow anomalies and other irregularities to ensure immediate response.

- Paperless Workplace. Our new digitized document system has successfully reduced paper consumption and storage by 80%.

- We recently reduced our use of compressed air by 23%. We filter all processes that emit particles and potentially harmful fumes – this air is then recycled and reused.

- A fully programmable Variable Frequency Control (VFD) by Trane on all HVAC systems. VFD allows us to run our HVAC systems at 48% capacity on an average day.

- Reduce. Reuse. Recycle. During our injection molding process, we regrind all non-fill parts to eliminate seconds and extra waste.

In addition to these current green initiatives, we’re continually investigating other ways to ease Wearwell's impact on the environment.