Replacing mats on time is important for worker health, safety, and housekeeping. Below we discuss some of the main signs we see that indicate matting needs to be replaced:

- Excessively Stepping On/Off the Mat

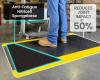

When purchasing mats, you buy it for the safety and ergonomic benefits. Continually stepping off the mat, (see photo above) lessens the ergonomic benefits of matting and you may put your team members in unnecessary danger. The chances of tripping over a mat increases greatly as the number of times a team member steps off (and back on) the mat. You need to replace the mat with product that can be made as large or wide as you need. To further increase safety and to prevent fatigue, use ergonomic floor tiles to replace overworn areas and recreate a fully supportive flooring solution for the worker to stand upon.

- The mat is ripped

Ripped mats are a poor reflection for any home or business but also pose a safety risk. Ripped mats tend to harbor uneven standing surfaces and scattered debris. While these are often trip hazards, employees still use them for any minimal bit of relief from concrete. For better luck, replace the mat with a hardier mat with a rip proof surface. Diamond mats and Marbled patterns are popular. Don’t let ripped mats hold you back from peak ergonomic performance.

- The mat is not a typical mat

If you think standing on a ripped mat is a poor idea, many team members have even less options when it comes to anti fatigue matting. When workers are standing on something that is not even a mat, there is a clear safety and ergonomic problem due to tripping and slipping risks. Cardboard, old rugs, wood planks, and pallets are examples of makeshift foot relief that employees will use to avoid solid concrete. A well-made, ergonomic mat would help these employees work harder and feel better at the end of the work week.

4. The mats have obviously failed or become hazardous

If a matting or flooring solution leaves considerable gaps in work areas, team members must perform their work while repeatedly stepping over trip hazards and uneven flooring. Luckily, there is a better way, and future trips to the disabled list can be avoided with something that actually stays together and doesn’t cause a trip hazard. Replace these mats with next generation ergonomic, modular products or other types of modern flooring options and watch your home or business’ ergonomic and safety needs quickly improve.

5. The mats are stacked

If floor mats are stacked one on top of the other, a new mat is needed to replace the old mats. Stacked mats create a major trip hazard for obvious reasons. Stacking means that the mats are worn through and need to be replaced. UltraSoft mats are a great replacement to be sure you have the necessary cushion going forward. Choosing the correct non-slip, ergonomic mat is crucial to avoid cases of stacked mats that cause excess material and danger.

- The Mat Is sliding

If a mat is sliding on the floor, it can just as easily slip and slide right out from under a work surface or team member. Sliding mats are an annoyance, and they can make a facility look sloppy. Workers must reposition them during work hours, and often the mats return to their ineffective positioning. Thankfully, this is another matting problem that can become one of the past. Replace sliding mats with matting equipped with anti-slide matting technology for a safe and ergonomic solution for your team or home.

- Bonus: Makeshift, unsafe methods are used to raise workers

Pallets and other makeshift solutions are not an effective way to improve performance as a matting or flooring solution. These can become a safety hazard to employees and must be replaced. Pallets should never be employed to lift workers to their work, and other makeshift methods are costly, unforgiving, and take too much time to build. If you need a raised platform with a solid foundation, there are safe and ergonomic options which can create work platforms as small or large as needed.