Mats Vs. Insoles: Read Before You Buy

You are looking into an insole program and deciding whether to move forward. You probably have a lot of questions like why do companies use insoles? Do insoles work? Do insoles prevent pain? Should I use mats or insoles? Here we discuss some of the differences between anti-fatigue mats and insoles when compared apples to apples:

1. Insoles do not prevent slips

There will always be slick spots, wet workstations, and other types of work environments where insoles are useless. In this case, a mat will still be necessary to solve a slip issue. Manufacturing environments are vastly different. If there are wet spots, dry dust, oils, etc, a mat is the best option to prevent slips.

2. Insoles do not prevent impacts

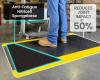

If someone falls and hits their head on a mat, the chances of injury are far less than on concrete. Insoles do not prevent these injuries like mats do. If an insole is the only thing supporting a team member, they still risk a much greater injury from a fall on concrete vs falling on a mat.

3. Insoles are a consumable

Companies love selling consumables, because it guarantees them future profits and a continued stream of YOUR MONEY! Insole companies take this approach. According to the insole company Power Step, (every employee’s) insoles should be replaced every 6 months! This short purchase cycle ends up costing far more over time than generally expected, and far more than a long-lasting mat. Plus, there are many mats with a Lifetime Warranty.

4. Insoles have continuous administrative costs

Somewhere by someone, insole sizes must be recorded in a database by size, person, date purchased, and when the re-purchase should be. That also includes adding every new employee to the insoles database, purchasing for them out of rhythm, and ensuring that they are using the insoles in the first place. This is as opposed to the right mat. When you work with an expert to choose the correct matting solution, you can put the mats down and they become part of the floor for the next 5 years, doing their job silently and diligently. And mats work without the use of a database to manage.

5. Unlike mats, insoles are not 1-size-fits-all

We mentioned that insoles of different sizes must be managed in a database. There are many different size insoles that will need to be purchased, from the smallest and daintiest feet, to very large and heavy feet. According to Sizecharter.com, women’s shoe sizes range between 4 and 12, while men’s sizes range between 6 to 16. Even without half sizes, this means nearly 20 different insole sizes to consider.

6. Many workers will choose not to wear the insoles anyhow

Workers are independent, and they take pride in that independence. If they don’t find the insoles helpful, or they don’t like the company telling them what to do, they won’t wear them. People buy their shoes because they like the way they feel in the first place. It seems silly to ask someone to put insoles into a brand-new pair of quality shoes. And for the workers who choose not to wear the insoles, that choice will also need to be recorded in a database so the information can be used when the time comes to re-purchase for employees.

7. Shoes in 2021 have high quality insoles out of the box

It sounds silly, but shoe and insole technology have come a long way. This isn’t the 1950’s where everything was made of solid rubber and leather. Companies have perfected designs, and make high quality, ergonomic, and comfortable shoes/ boots that already come with great insoles. Replacing an insole that was designed for a specific shoe is probably not recommended by the shoe manufacturer in the first place.

In conclusion:

If someone is looking for insoles, we recommend Dr. Scholl’s. There is no magic insole which is so much better than any other, but the disadvantages to insoles are many, especially trying to manage a program in a manufacturing environment. It pays to consult a matting expert, get some professional recommendations, and go from there- with all the information.