About

Wearwell is dedicated to developing innovative products that improve morale, productivity and safety of standing workers.

Over the past 20 years, Wearwell has been first to market with many products that have moved the market forward and changed the industry. The following are those that most revolutionized anti-fatigue matting.

Wearwell has introduced more successful ergonomic and safety surfaces than anyone in our industry.

We develop game-changing products that solve specific workplace challenges. Innovative design can mean the difference between a product that is “good enough and one that energizes your team.

We create products that solve specific problems

At Wearwell we never introduce a product just because; we create products that meet specific needs. Often, we fulfill needs no one knew existed.

For example, when we introduced ESD (static control) anti-fatigue mats in the mid 80s, we filled a market need for the booming microelectronics industry that no one else was serving. We’ve done this again and again for the lab and pharmaceutical marketplace, food production, and industrial environments of every kind.

The importance of design

Innovative design and clean aesthetics set Wearwell products apart. Examples include ErgoDeck’s patented interlock system, Grade A’s built-in handles, OutFront's versatility, InVision’s lasting edge to edge graphics... the list goes on. Let us prove to you the difference great design can make in your workplace.

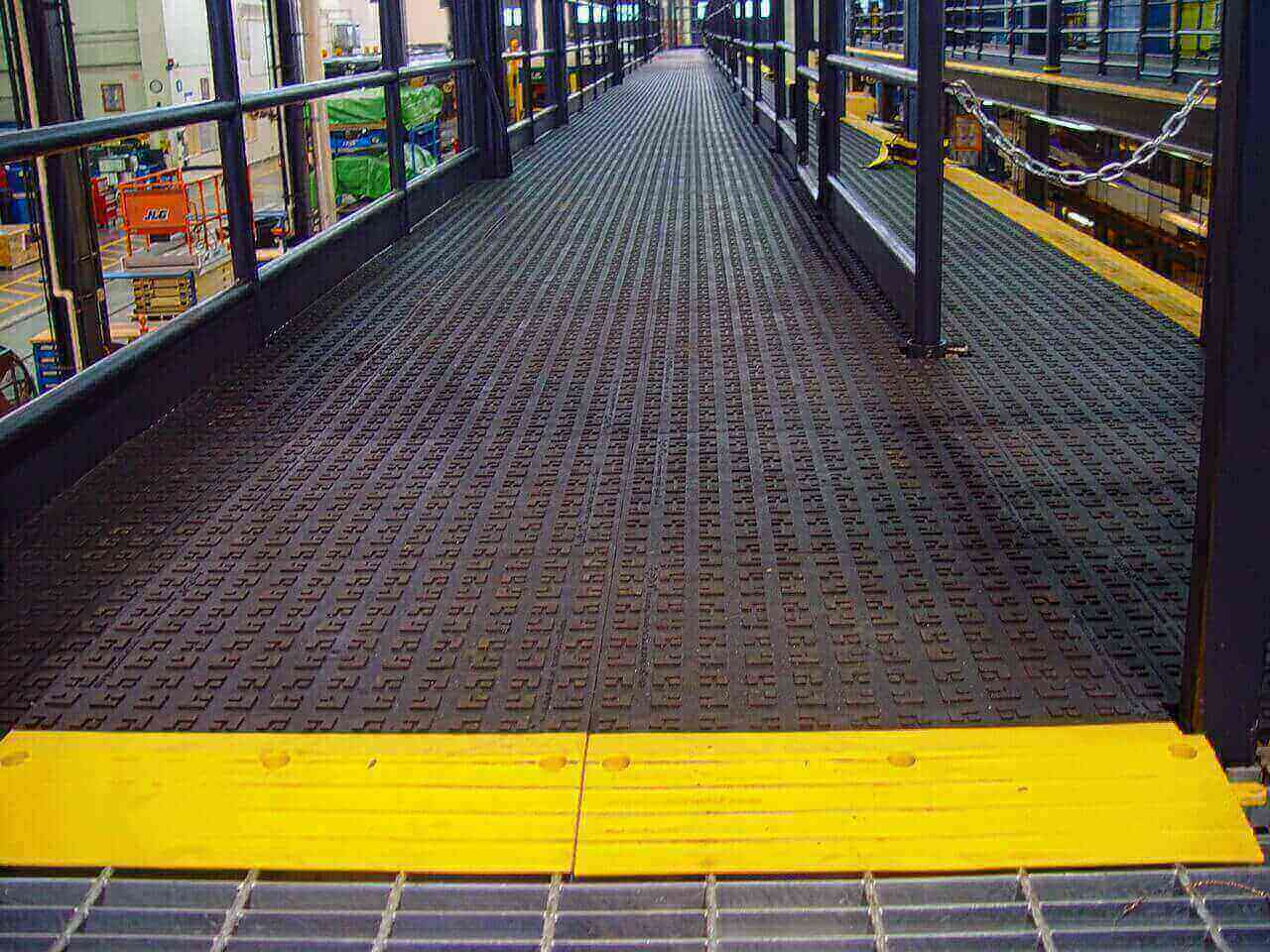

2013 ErgoDeck w/ No-Slip Cleats

Like traditional playing surfaces, gritted products give some temporary traction but wear with use and become slippery with saturation. Cleats are a tried and true means to overcome such harsh field conditions.

2013 InVision No. 110

InVision is the ultimate pick for custom printed anti-fatigue matting. Unlike other printed mats, we print on the underside of a clear 5/16” thick surface. That means your graphic never comes in contact with foot traffic to help protect it from wear.

2013 ROVER No. 515

A unique breed of kneel mat, ROVER™ delivers support where you need it most.

2012- GRITSHIELD

Increases traction in areas where slips and falls are a major concern. Our unique grit system provides an exceptionally high level of traction and durability and is available over colors!

2010- F.I.T.

Easily tackle large and small areas with F.I.T. These lightweight 12” x 12” interlocking tiles feature our patented LockSafe® system. Simply snap together to form secure connections for dependable floors and surfaces.

2011 – Vitality No. 502 modular runners

Vitality® is the ultimate ergonomic floor in terms of comfort and construction. Large modular tiles interlock on all four sides to customize on-site virtually any flooring configuration. Interlocking ends and centers are also available to quickly and easily fabricate long runners.

2011- Double Duty Switchboard No. 720

Our Premium Nitricell® sponge is what makes Double-Duty the first in class for comfort and safety.

2009- SMART™ Diamond-Plate No. 497 and Tile-Top No. 496

The diamond-plate pattern is, without question, the most popular surface design in ergonomic matting, and for very good reasons. Diamond-plate is easy to clean and tough! It provides good traction to help prevent slips and falls.

The marbleized appearance of the Tile-Top matting products is consistent with flooring commonly used in laboratories, pharmacies and medical environments. Plus, the smooth surface is desirable in applications where cleanliness is a very high priority.

2008 – Vitality 502 – Modular Urethane tiles

Modular tiles allow on-site customization for any area size or configuration. The ultimate ergonomic safety solution for standing and walking workers.

2007 - Autoclavable Mat No. 580

The original autoclavable mat for sterile environments. Designed for use in operating rooms, pharmacies where medicines are mixed, laboratories, radiology rooms and HazMat areas, this unique mat is non-porous and anti-microbial. True to its name, it will withstand extensive autoclaving at 275 degrees Fahrenheit and 15 psi. This remarkable mat was created for hygienic areas where employees were previously not allowed to use mats.

2007 - Tile-Top AM No. 420

Provides the same timeless appeal and exceptional feel as original Tile-Top SpongeCote, but is now 100% anti-microbial. The improved, permanently anti-microbial surface is able to destroy microorganisms on contact and can result in a significant reduction of air-borne contaminants. This non-porous vinyl surface is also constructed with an extra wear layer for exceptional abrasion and chemical resistance. The mat's exceptional comfort comes from its micro-pure™ sponge base. This unique Nitrile rubber composite is specifically designed for exceptional resilience and long life, and also offers permanent anti-microbial properties.

2006 - Grade A THE Food Production Mat No. 482

The first mat specifically designed for food production facilities. While other mats have been sold to food production facilities, Grade A™ is the first with a design that virtually eliminates areas where food particles can collect. This clean, functional design with built-in handles and an anti-microbial rubber compound have sent this mat to the top of the new product charts.

2006 - OutFront Reversible Scraper Mat No. 227

A revolutionary reversible outdoor scraper mat that lasts twice as long as other outdoor mats and functions in all seasons.

2006 - ErgoDeck SOFT (now General Purpose)

A softer version of the original ErgoDeck™, it appeals to those who desire extra comfort.

2004 - ErgoDeck

The first 18"x18" supersized modular ergonomic tile that locks together to create a seamless “floor above a floor.” The ErgoDeck™ system is designed for heavy-duty production environments where durability and productivity are key. We attribute much of its phenomenal success to its total functionality and patented interlock design.

2004 - Cutting Fluid Resistant Rubber

Wearwell's breakthrough formulation has yet to be duplicated. CFR stands for Cutting Fluid Resistant and will withstand the effects of mineral oil-based cutting fluids.

2002 - Diamond-Plate w/ GritWorks! No. 416

A brilliant idea that emerged from the auto industry. We were asked if we could combine the comfort of Diamond-Plate with the traction of GritWorks!®. The answer was a resounding "yes!" The final product proved perfect for areas where grease and oil are tracked.

1998 - Vitality No. 501

The original and still totally unique encapsulated urethane sponge mat. Virtually indestructible, the combination of tough outer urethane skin and resilient inner urethane sponge gives the product the durability to provide many years of comfort.

1997 - GritWorks! on Molded Rubber

The first high traction molded rubber anti-fatigue mats. The goal was to make one of our most comfortable “wet area” mats slip-resistant as well. So we created the first rubber molded mats with a high traction, gritted surface. Buoyed by the success of these GritWorks!™ products, we improved the product five years later by developing a cutting fluid resistant formulation (CFR) and enhancing the COF (coefficient of friction) of the grit. Our latest innovation of this line is a petrochemical resistant Nitrile compound, exceptionally unaffected by petroleum and hydrocarbon based fluids.

1996 - WeldSafe No. 447

The original mat for spot welding areas. A practical solution, WeldSafe withstands hot metal shards and provides exceptional comfort in an application where no mats would work before. Its surface has an extremely high melt point that resists pockmarking when exposed to sparks and small shards.

1994 - UltraSoft Diamond-Plate No. 414

We took the best product on the market, Diamond-Plate SpongeCote®, and made it even better. Thicker, softer, and longer lasting than the original, UltraSoft soon began to outsell the original Diamond-Plate and spawned a market for extra-thick, super high performance anti-fatigue mats.

1992 - Electrically Conductive Anti-fatigue No. 786

The first anti-fatigue mats to meet the unique needs of the emerging tech industry. These mats combined static control with professional grade comfort. Initially designed for the semiconductor industry, these products quickly became popular in regular industrial settings. Over the next few years we rounded out the line with several molded rubber anti-fatigue mats and a popular tabletop mat for the electronics industry.

1989 - Diamond-Plate SpongeCote No. 415

The #1 best-selling industrial mat of all time and the anti-fatigue mat that redefined the industry. Diamond Plate SpongeCote® virtually took the market by storm because it was the first truly industrial mat with a sponge backing.

1987 - WorkSafe Light No. 478

The first lightweight rubber drainage mat designed to optimize human performance. To this point, all rubber anti-fatigue mats were at least 19 mm thick and very heavy. We designed WorkSafe Light to offer the same comfort with 40% less weight. This simplified maintenance and dramatically reduced the potential for back strains.